Power Up: Transform Your UTV with Engine Upgrades

Release Your UTV's True Potential

If you're looking to upgrade your UTV's performance, here are the most essential UTV engine parts to consider:

- Drive Belts: Replace every 1,500-2,000 miles for optimal power transfer

- Pistons and Rings: Critical for compression and power output

- Gaskets and Seals: Prevent fluid leaks and maintain pressure

- Air Filters: Improve airflow for better performance

- Oil Filters: Ensure clean oil circulation to reduce engine wear

- Clutch Components: Optimize power delivery for your terrain

- Turbochargers: Add significant horsepower for challenging conditions

UTV engine parts are the foundation of your vehicle's performance and reliability. Whether you're racing through desert terrain, navigating muddy trails, or climbing rocky mountains, your UTV's engine is the heart that powers every trip. With the right upgrades and maintenance, you can significantly boost power, improve reliability, and extend the life of your machine.

Most stock UTVs leave plenty of performance on the table. The good news? You don't need to be a mechanical engineer to make meaningful improvements. From simple maintenance replacements to major performance upgrades, the right parts can transform your riding experience without breaking the bank.

Signs that you might need to upgrade include loss of power, excessive oil consumption, blue smoke from the exhaust, or unusual engine noises. Regular maintenance with quality components can prevent these issues before they start, saving you money and downtime in the long run.

I'm Robert Resz, founder of Rad UTV Parts and a lifelong off-road enthusiast with extensive experience testing and installing premium UTV engine parts across diverse terrains and challenging conditions. My hands-on expertise has helped countless riders maximize performance while maintaining reliability in their machines.

Basic UTV engine parts glossary: - UTV replacement parts - UTV sway bars - UTV off-road accessories

What You'll Learn

In this comprehensive guide, we'll walk you through everything you need to know about UTV engine parts and performance upgrades. Whether you're a weekend warrior or a serious off-road enthusiast, you'll find actionable advice that can be applied to virtually any UTV make and model.

We've designed this guide to be DIY-friendly, with expert tips and insights that will help you make informed decisions about your UTV's engine components. From basic maintenance to advanced performance modifications, we've got you covered.

By the end of this article, you'll understand: - Which engine parts are most critical for performance and reliability - How to diagnose common issues before they become expensive problems - When to replace, rebuild, or upgrade your engine components - The differences between OEM and aftermarket parts - How to select performance upgrades that match your riding style - Step-by-step approaches to common engine modifications

Let's explore how you can transform your UTV's performance with the right engine parts and upgrades.

UTV Engine Parts 101: The Building Blocks of Power

Ever popped the hood of your UTV and wondered what's really making all that magic happen underneath? Let's break down the heart and soul of your off-road beast - the engine parts that turn fuel into adrenaline-pumping trip.

Your UTV's engine isn't just a metal box making noise - it's a carefully orchestrated team of components working together to get you through mud, over rocks, and across deserts. Understanding these parts isn't just for mechanics - it's for anyone who wants their machine to perform better and last longer.

The powerhouse of your UTV relies on several critical UTV engine parts working in perfect harmony. Your pistons and rings create the compression needed for combustion, moving up and down in the cylinders while maintaining that crucial seal. The cam chain drives your camshaft, controlling when valves open and close - when this wears out, your timing goes haywire, and performance suffers.

Your valve train (including valves, springs, and lifters) manages the flow of air, fuel, and exhaust gases, while the crankshaft transforms all that up-and-down piston movement into the rotational force that eventually reaches your wheels. Don't overlook the importance of gaskets and seals - these humble components prevent fluids and gases from leaking where they shouldn't.

Throughout your engine, bearings reduce friction between moving parts, allowing everything to operate smoothly while preventing premature wear. And while technically part of the transmission system, your drive belt is the critical link transferring power from the engine to the wheels in most UTVs.

Rounding out the team are your oil filter, removing harmful particles from your engine oil, and your cooling pump, which circulates coolant to keep temperatures in the sweet spot for performance.

Essential UTV engine parts glossary

Let's dig deeper into these UTV engine parts and their specific roles in keeping your ride running strong:

The cylinder block forms the main structure of your engine, housing the cylinders, cooling passages, and crankcase, while the cylinder head sits on top containing combustion chambers, valves, and spark plugs. Your aluminum alloy pistons move within the cylinders, compressing the air-fuel mixture, with piston rings creating that critical seal against the cylinder walls.

Connecting rods link your pistons to the crankshaft, transferring explosive force into rotational motion. The camshaft controls valve timing via lobes that push against valve lifters, while the timing chain synchronizes the rotation of the crankshaft and camshaft. Valve springs ensure valves return to their closed position after opening.

Your intake manifold distributes the air-fuel mixture to each cylinder, while the exhaust manifold collects spent gases. The oil pump circulates vital lubrication throughout the engine, and fuel injectors spray precisely measured amounts of fuel. Overseeing it all is your ECU (Engine Control Unit) - the brains of the operation controlling ignition timing and fuel delivery.

Heat management is absolutely crucial for these components. Excessive temperatures lead to premature wear, reduced performance, and potentially catastrophic failure. That's why modern UTVs employ sophisticated cooling systems including liquid cooling with radiators and oil coolers for transmission components.

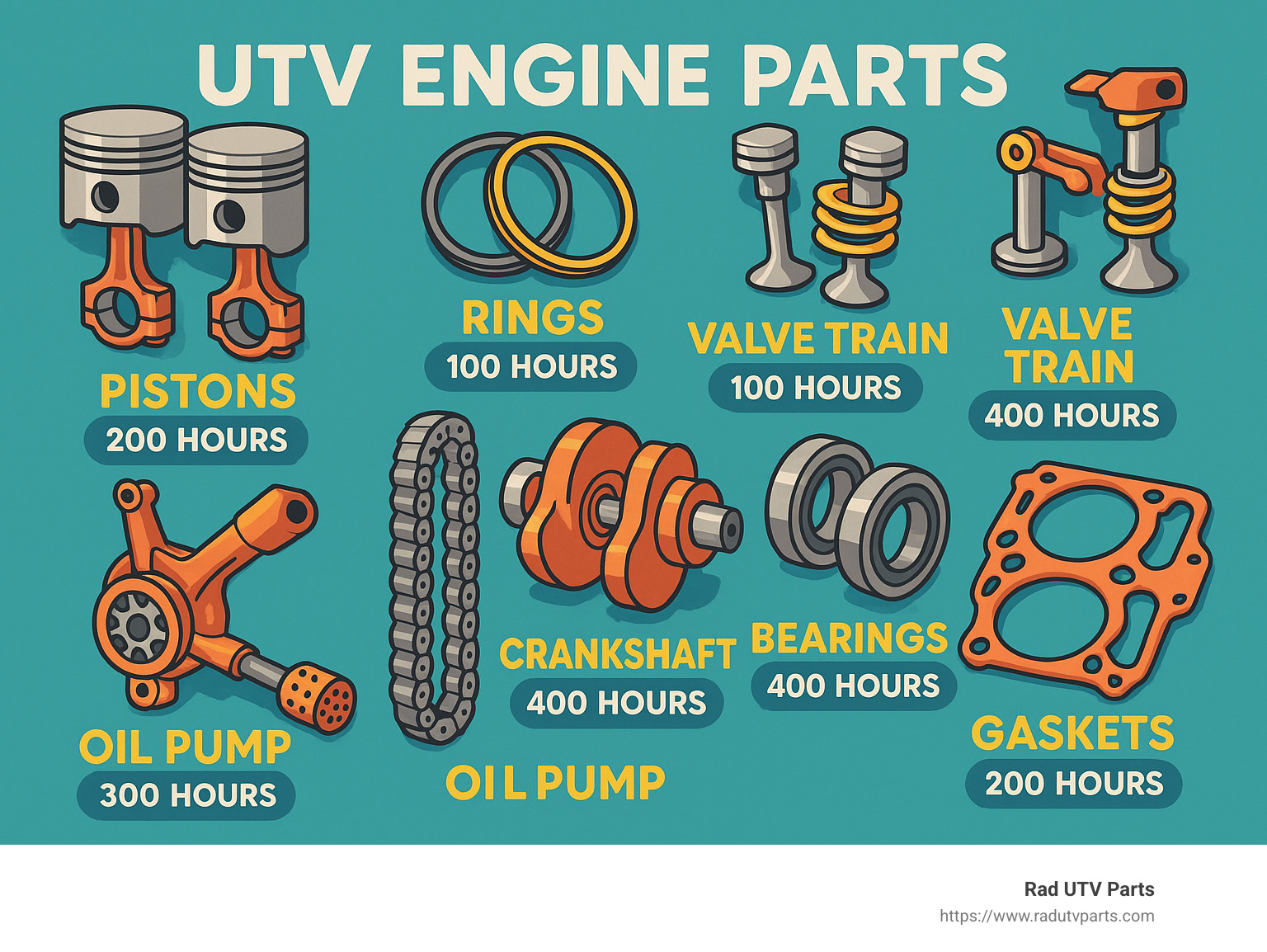

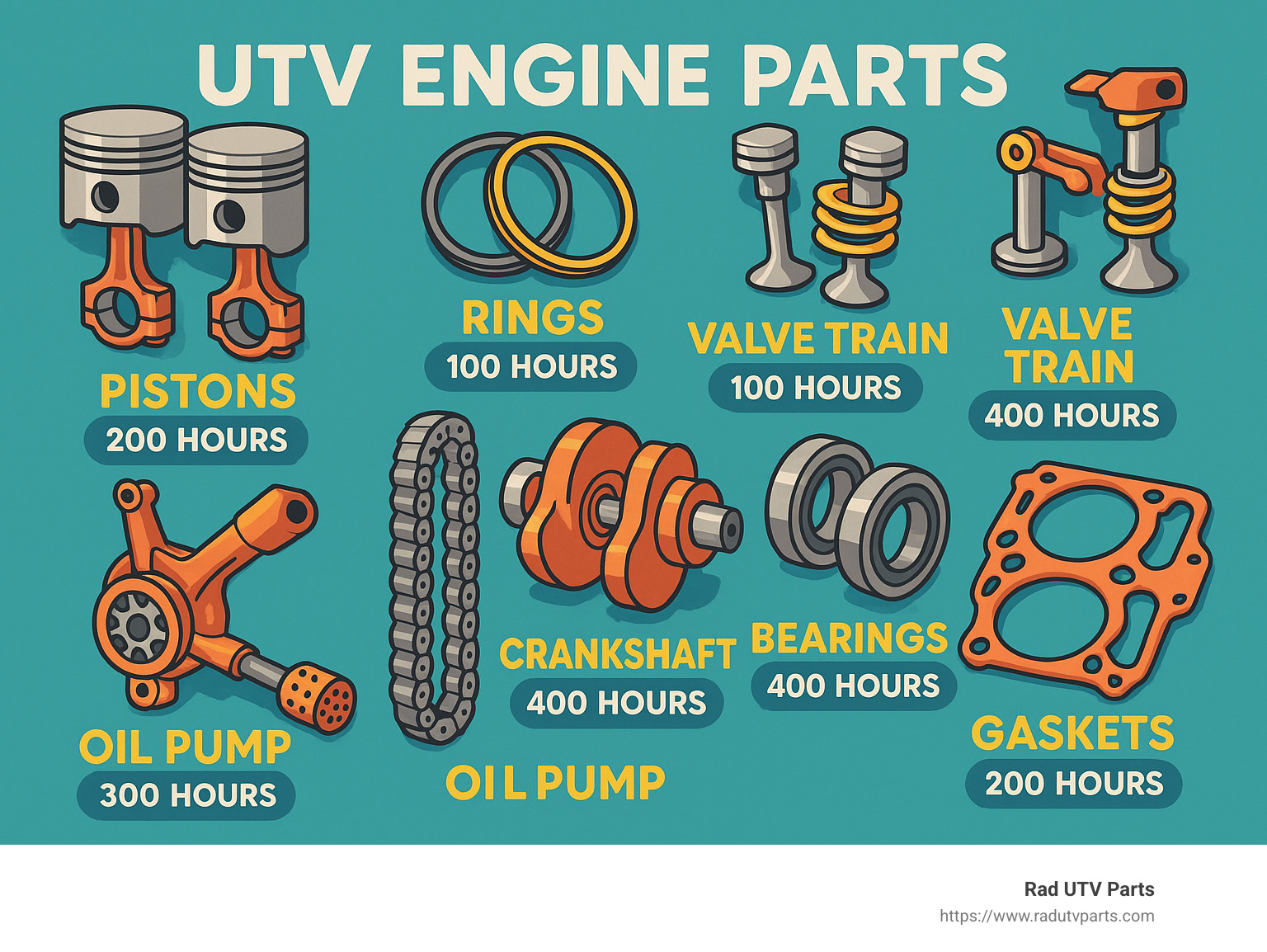

Most-replaced UTV engine parts & mileage averages

Based on what we've seen in the field and heard from countless customers, here are the UTV engine parts that most commonly need replacement:

Your drive belt typically needs replacement every 1,500-2,000 miles, though this varies dramatically based on how and where you ride. Mud bogs, water crossings, and aggressive driving can cut belt life significantly. Watch for visible cracks, fraying edges, or a glazed appearance.

Pistons and rings endure tremendous heat and pressure. In high-performance or heavily used UTVs, plan on inspection or replacement every 5,000-10,000 miles. When they're wearing out, you'll notice reduced compression, increased oil consumption, and telltale blue smoke from your exhaust.

Gaskets and seals throughout your engine will deteriorate over time, typically needing replacement when leaks appear around 5,000-8,000 miles, depending on riding conditions and maintenance. Engine bearings, including main and rod bearings, usually last 5,000-10,000 miles in well-maintained UTVs. If you hear knocking sounds, especially under load or at idle, your bearings may be telling you something.

Valve train components may need service every 5,000-8,000 miles, especially if you're riding in dusty environments or running at high RPMs regularly. Your oil pump should last 8,000-10,000 miles but can fail earlier if you're using contaminated oil or skipping maintenance.

Cam chains and tensioners often need replacement or adjustment around 5,000-8,000 miles. Listen for rattling noises, especially during startup or when you let off the throttle. While not internal engine components, air filters need cleaning every 500-1,000 miles and replacement every 2,000-3,000 miles (more often in dusty conditions), while oil filters should be replaced with every oil change.

Engine-exploded view showing wear hot-spots

The image above highlights the common wear points in a typical UTV engine. These high-stress areas demand the most attention when maintaining your ride:

The piston ring/cylinder wall interface experiences significant friction and heat, causing wear on both rings and cylinder walls over time. Valve seats and guides undergo constant opening and closing, creating wear particularly at high RPMs.

Cam lobes and lifters experience substantial metal-to-metal contact, especially during cold starts before oil pressure builds. Your main and rod bearings support the crankshaft and connecting rods under tremendous forces, while timing chain guides and tensioners wear constantly due to friction with the chain.

The head gasket sealing surfaces between your cylinder head and block experience extreme temperature changes and pressure, making them prone to failure if not properly maintained.

Understanding these wear points helps you prioritize maintenance and upgrades for maximum reliability. At Rad UTV Parts, we've seen it all - and we know which parts need the most attention to keep you riding rather than wrenching.

When & How to Service: Replace, Rebuild or Upgrade

Every UTV owner knows that sinking feeling when something just doesn't sound right under the hood. Your once-powerful machine starts to hesitate on hills, or you notice a thin blue haze trailing behind you on the trail. These aren't just minor inconveniences—they're your UTV trying to tell you something important about its UTV engine parts.

The good news? By catching these warning signs early, you can often prevent a small issue from becoming a wallet-emptying disaster. Let's talk about what to watch for and what to do when your UTV starts showing signs of engine wear.

That strange knocking sound or sudden power loss isn't just your imagination. Common symptoms that suggest your UTV engine parts need attention include a noticeable drop in power (especially when climbing), blue smoke puffing from your exhaust, oil disappearing between rides, distinctive knocking or ticking sounds, frequent overheating, rough idling, or finding tiny metal particles in your oil during changes.

Any of these symptoms means it's time to take a closer look—ignoring them only leads to more extensive damage and costlier repairs down the road.

Diagnosing worn UTV engine parts

Before you start ordering replacement parts, it's worth taking the time to pinpoint exactly what's going on inside your engine. A proper diagnosis can save you hundreds in unnecessary parts and labor.

The compression test is your best friend here. This simple procedure measures the pressure in each cylinder during cranking, with healthy UTV engines typically showing readings between 150-180 PSI (though always check your specific model's service manual for the correct numbers). Low readings point to issues with valves, rings, or head gaskets.

For more detailed insights, consider a leak-down test, which pressurizes the cylinder and helps identify exactly where compression is escaping. Oil analysis can reveal microscopic metal particles that tell you which internal components are wearing out.

A borescope inspection lets you actually see inside your engine through the spark plug hole without taking anything apart—it's like having X-ray vision for your UTV! This visual check can reveal scoring on cylinder walls, damaged pistons, or burnt valves before they cause catastrophic failure.

Accurate diagnosis isn't just about fixing what's broken—it's about understanding why it broke so you can prevent it from happening again.

Replace vs rebuild decision tree

So you've diagnosed the problem—now comes the big decision: replace a few parts, rebuild the entire engine, or swap in a remanufactured or new powerplant? Each option has its place depending on your situation.

Individual component replacement makes sense when the issue is isolated to specific parts like a worn drive belt or failing oil pump. This approach works well if you have decent mechanical skills, the rest of your engine is in good shape, and your budget is tight. It's the least expensive route but requires accurately diagnosing the problem.

A complete engine rebuild becomes the logical choice when multiple components show significant wear. This option lets you upgrade parts during reassembly and can save money compared to a new engine, but be honest about your mechanical abilities and available time—engine rebuilds typically require 20-40 hours of skilled labor and a proper workspace.

Remanufactured engines offer a compelling middle ground. They provide reliability with warranty coverage, minimize downtime (typically 8-12 hours for installation versus weeks for a rebuild), and don't require advanced mechanical skills. For many owners, especially those who depend on their UTV for work or planned trips, the convenience factor alone makes this option worthwhile.

New factory engines represent the premium solution. They make sense for newer, valuable UTVs where reliability is paramount and budget isn't as restricted. They typically come with the best warranty coverage and incorporate any recent factory improvements or updates.

The downtime factor shouldn't be overlooked—a rebuild might leave your UTV in pieces for weeks while you wait for parts or find time to work on it, whereas an engine swap can often be completed in a weekend.

Step-by-step engine rebuild overview

If you've decided to tackle a rebuild yourself, knowing what you're getting into before starting can make the difference between success and a garage full of parts that never quite make it back together.

Start with thorough documentation and preparation. Take photos from multiple angles during disassembly—you'll thank yourself later when reassembling. Label everything carefully, invest in a quality service manual specific to your model, and prepare a clean workspace with organized storage for hundreds of parts and fasteners.

During disassembly, work methodically from the outside in. Remove the engine from the UTV, then strip external components like intake, exhaust, and accessories before tackling the cylinder head, valves, and cam. Continue with pistons and connecting rods, and finally extract the crankshaft and bearings. Clean each component thoroughly for proper inspection.

The inspection phase is critical—this is where you determine what can be reused and what must be replaced. Measure cylinder bores for wear and roundness, check crankshaft runout and journal condition, inspect connecting rods for straightness, examine valves and seats for damage, verify camshaft lobe profiles, and inspect all bearings for signs of wear or scoring.

Based on your inspection, you'll likely need some machining work. This might include boring or honing cylinders, resurfacing the cylinder head if warped, or turning crankshaft journals. This is typically done by a machine shop unless you have specialized equipment.

Reassembly is where the magic happens. Use assembly lube or clean oil on all components, install the crankshaft with proper bearing clearance, mount connecting rods and pistons, reassemble the valve train with correct clearances, install the timing chain with proper tension, and torque all fasteners to specification using a calibrated torque wrench.

The break-in procedure is just as important as the rebuild itself. Prime the oil system before starting, then follow a specific break-in regiment that involves varying RPM and avoiding heavy loads. Change oil and filter after the initial break-in period, recheck all fasteners, and gradually increase performance demands over the first 100-200 miles.

Benefits of remanufactured engines

For many UTV owners, remanufactured engines offer the sweet spot between quality, convenience, and affordability. These aren't just used engines—they're completely disassembled, inspected, machined, and rebuilt to exacting standards.

The cost savings are substantial, typically 30-50% less than new factory engines while delivering comparable performance and reliability. There's also an environmental benefit, as remanufacturing reuses the core components instead of requiring all-new materials and energy.

Professional rebuilders use industrial equipment and standardized processes that often exceed what's possible in a home garage. Their specialized machines can achieve tolerances and surface finishes that directly translate to longer engine life.

Warranty coverage provides peace of mind that DIY rebuilds can't match. Most remanufactured UTV engine parts come with a 6-month warranty, and as one industry leader states: "We are the first to offer remanufactured UTV engines with a full six-month warranty and an optional six-month extension, making us the first to offer a one-year warranty in the industry."

Many remanufacturers incorporate upgraded components that address known weaknesses in the original design—things like improved oiling systems, better bearings, or more durable valve seats. These improvements can make a remanufactured engine even more reliable than the original.

The reduced downtime is significant—with a remanufactured engine, you can typically have your UTV back on the trails in days rather than weeks. Most rebuilders also offer core exchange programs where you receive credit for returning your old engine, further reducing the overall cost.

Maintenance schedule that prolongs life

The best repair is the one you never have to make. Following a proper maintenance schedule dramatically extends engine life and maintains peak performance. Think of it as cheap insurance for your expensive toy.

After every ride, take five minutes to check oil level and condition, inspect your air filter for debris, listen for unusual noises during shutdown, check for fluid leaks, and verify your cooling system is working properly. These quick checks can catch small issues before they become major problems.

Every 500-1,000 miles (or 50 hours of operation), change your engine oil and filter—more frequently if you ride in dusty conditions. Clean your air filter, inspect your drive belt for wear and proper tension, check valve clearance, and examine your spark plug condition. These basic services prevent the most common causes of premature engine wear.

At the 2,000-3,000 mile mark (or 100 hours), replace that air filter regardless of how it looks, change transmission fluid, inspect your fuel system for leaks, adjust valve clearance if needed, check cooling system hoses for deterioration, and install fresh spark plugs.

By 5,000 miles, it's time for more thorough maintenance: inspect timing chain tension, check cylinder compression, flush the cooling system and replace coolant, clean fuel injectors, examine engine mounts for damage, and perform a complete valve adjustment.

When you hit 10,000 miles, consider a borescope inspection of pistons and rings, check bearing clearances, inspect the cam chain and guides, evaluate oil pump condition, and assess whether a rebuild might be on the horizon.

Remember to adjust these intervals based on how and where you ride. Mud, water crossings, desert dust, and high-performance driving all demand more frequent service. For more details about service intervals, check out our detailed service guide.

Following this maintenance schedule isn't just about preventing breakdowns—it's about maintaining performance, fuel efficiency, and the pure enjoyment of riding a UTV that runs at its best. Your engine will thank you with thousands of additional miles of trouble-free operation.

OEM vs Aftermarket UTV Engine Parts: Making the Smart Choice

When it comes time to replace worn UTV engine parts, you'll face a critical decision that impacts both your wallet and your vehicle's performance: should you go with Original Equipment Manufacturer (OEM) parts or explore aftermarket alternatives?

Think of this choice like selecting ingredients for your favorite recipe. OEM parts are like buying the exact brand-name ingredients listed in the cookbook—they're guaranteed to work exactly as intended, but you'll pay a premium. Aftermarket parts are more like shopping at a specialty store where you might find higher-quality or more affordable alternatives that could actually improve the dish.

OEM parts offer the peace of mind that comes with perfect fitment and factory specifications. They're identical to what came in your UTV originally, which means installation is typically hassle-free. The quality control tends to be consistent, and using them won't raise any eyebrows if your vehicle is still under warranty. The downside? You'll typically pay 30-50% more, and you're stuck with any inherent design flaws from the original.

Aftermarket parts, on the other hand, often deliver more bang for your buck. Many aftermarket manufacturers have studied OEM designs and improved upon them, using better materials or improved designs to address known weaknesses. You'll usually save 20-40% compared to OEM prices, and you'll have more options to choose from. The challenge is sorting through varying quality levels—some aftermarket parts are superior to OEM, while others might leave you stranded on the trail.

| Criteria | OEM Parts | Aftermarket Parts |

|---|---|---|

| Cost | Higher | Lower (typically 20-40% less) |

| Quality | Consistent | Varies by manufacturer |

| Fitment | Perfect | May require adjustments |

| Performance | Stock | Potential improvements |

| Warranty | Maintains factory warranty | May affect warranty coverage |

| Availability | Sometimes limited | Usually more options |

| Material Options | Limited | Multiple choices |

| Design Improvements | Rare | Common |

Many experienced UTV owners take a hybrid approach: using OEM for critical engine components where precise fit is essential (like crankshafts or electronic control units) while selecting high-quality aftermarket parts for areas where performance gains are desirable (such as air intakes or exhaust systems).

Cost breakdown & typical repair bills

Understanding what you might spend on UTV engine parts helps you plan ahead and avoid sticker shock when something breaks. Let's look at what typical repairs might cost you:

Basic maintenance items won't break the bank. You'll spend about $10-25 for an oil filter, $25-60 for an air filter, and $15-30 for each spark plug. Drive belts—one of the most commonly replaced items—typically run between $100-300 depending on your model.

When you get into engine internals, prices climb quickly. A piston kit with rings, pin, and clips will set you back $150-350 per cylinder. If you need a complete cylinder kit, budget $400-800. Crankshafts are among the priciest components at $500-1,200, while connecting rods typically cost $150-300 each. A complete gasket kit usually runs $150-400.

Labor costs add substantially if you're not doing the work yourself. A simple oil and filter change might cost $75-150 at a shop, while a drive belt replacement typically runs $150-300. For more extensive work, expect to pay $800-1,500 for a top-end rebuild or $1,500-3,000 for a complete engine rebuild.

If you're considering complete solutions, a quality remanufactured engine typically costs $2,500-4,500—about half the price of a new OEM engine ($4,000-8,000). Performance engine builds can easily exceed $10,000 for high-end applications.

European and Japanese UTV models often carry higher parts costs than American-made vehicles. Doing the work yourself can save 40-60% on labor, but requires proper tools and mechanical knowledge.

Warranty & support essentials

When investing in UTV engine parts, the paperwork matters almost as much as the metal. Good warranty coverage and technical support can be the difference between a minor inconvenience and a major headache.

New OEM engines typically come with 6-12 month warranties, while quality remanufactured engines offer standard 6-month coverage. Some rebuilders now offer extended protection, as highlighted by one industry leader: "Engines come with a full six-month warranty—extendable to one year." This additional coverage provides valuable peace of mind for a relatively small investment.

Beyond the warranty period, return policies vary significantly. Most retailers offer 14-30 day return windows, but pay attention to who covers return shipping (which can be substantial for heavy engine components) and whether restocking fees apply. Many companies charge 15-25% restocking fees for returned parts, which can take a big bite out of your refund.

Technical support is another crucial consideration. Look for companies that offer phone support with knowledgeable staff, detailed installation instructions or videos, and perhaps access to online communities where you can get advice from other owners. Nothing beats being able to call someone who can walk you through a tricky installation step.

For major components like complete engines, core exchange programs can save you significant money. These programs give you credit for returning your old engine, but make sure you understand what constitutes an acceptable core, the core charge amount, and how to properly return your old parts.

At Rad UTV Parts, we prioritize making the warranty process painless because we understand that trail time is precious, and every day your UTV sits in the garage is a day you're missing out on trip.

How to pick parts for your exact model

Selecting the right UTV engine parts for your specific machine is like finding the perfect pair of jeans—close enough isn't good enough. Here's how to ensure perfect fitment every time:

Start by gathering your vehicle's vital statistics. Locate the VIN (Vehicle Identification Number) typically stamped on the frame, and document your engine's model number and production date. Knowing your specific trim level and factory options is also essential, as these can affect which components will fit properly.

With this information in hand, you have several research avenues. Most online retailers offer model-specific parts finders that filter products by your exact vehicle. Factory service manuals are gold mines of information, containing precise part numbers and specifications. Some manufacturers provide online VIN lookup tools that show exactly what equipment came on your UTV originally. Exploded view diagrams are particularly helpful for identifying components and understanding how they relate to surrounding parts.

Always verify your findings by cross-referencing part numbers between different sources. When possible, compare physical dimensions of new parts to your existing components. For less common applications, model-specific forums can be invaluable for learning about compatibility issues other owners have finded.

Be aware of hidden compatibility factors that might not be obvious. Year-to-year changes can affect fitment even within the same model line. Engine variations (displacement differences, turbo vs. non-turbo) often require different components. Some parts may physically fit but negatively impact performance if they're not designed for your specific configuration. And upgraded parts sometimes require additional modifications for proper operation.

For clutch components in particular, proper selection is critical. As you Learn more about clutch durability, you'll find how the right clutch parts can dramatically improve your UTV's performance and longevity.

At Rad UTV Parts, our specialists maintain detailed fitment databases covering virtually all UTV makes and models, helping ensure you get the right parts the first time and get back on the trail without unnecessary delays or frustration.

Performance Upgrades: From Belts to Turbos

Ready to release your UTV's hidden potential? Performance upgrades can transform your riding experience, whether you're looking for more power on steep climbs or faster acceleration on open trails. The best part? You don't need to be a mechanical genius to make meaningful improvements to your UTV engine parts.

Let's explore your options, from simple weekend projects to major performance overhauls that'll have your riding buddies wondering what you've done to your machine.

Bolt-on power adders that still preserve reliability

Adding power doesn't have to mean sacrificing reliability. In fact, some of the most effective upgrades are relatively simple to install and won't stress your engine components.

A high-flow air filter is often the perfect starting point. These filters allow your engine to breathe more freely, typically improving airflow by 10-15% and adding 2-5 horsepower. For $150-400 and about an hour of your time, it's hard to beat the value. The reliability impact is minimal as long as you keep up with regular cleaning.

Performance exhaust systems are another popular upgrade that can add 3-8 horsepower while giving your UTV a more aggressive sound. That throaty rumble isn't just for show—it's the sound of improved exhaust flow reducing backpressure on your engine. Installation usually takes 1-3 hours, and at $300-1,200, it's a worthwhile investment that won't harm reliability.

ECU tuning might seem intimidating, but modern programmers have made it surprisingly user-friendly. These devices can optimize your fuel and timing maps for better performance, often adding 5-15% more power depending on what other modifications you've made. For $300-800, these plug-and-play devices offer impressive gains with minimal risk when tuned conservatively.

Don't overlook cooling upgrades. While they don't directly add power, improved radiators and cooling systems prevent heat-related power loss when you're riding hard. This is especially important if you ride in hot climates or frequently tackle challenging terrain. Your engine will thank you for the $200-600 investment by performing more consistently and lasting longer.

Charge pipes and intercoolers are game-changers for turbocharged UTVs. By reducing intake air temperature, an upgraded intercooler creates a denser air charge that can add 5-10% more power and significantly improve consistency. The $500-1,200 price tag is justified by both the performance gain and the reduced risk of detonation.

When combined thoughtfully, these modifications create a package where the total improvement exceeds what you'd expect from adding up the individual gains. That's the beauty of a well-planned upgrade path.

Clutching & drivetrain tweaks for more usable torque

Your UTV's clutch system is the unsung hero that determines how engine power reaches the ground. Even modest adjustments here can dramatically transform how your vehicle performs in real-world conditions.

Custom clutch kits are designed for specific riding conditions—mud, sand, trails, or rocks. They improve engagement characteristics and reduce belt heat, which means more power makes it to the wheels and your belt lasts longer. At $300-800, these kits take 2-4 hours to install but provide substantial improvements in usable power that you'll feel immediately.

Clutch weights alter shift points and engagement characteristics, allowing you to tune your UTV specifically for your terrain or riding style. Heavier weights typically improve low-end power, while lighter weights favor top-end performance. For $100-300 and a couple hours of work, you can significantly change how your UTV delivers power.

The helix or ramp angle in your secondary clutch changes how quickly it shifts. Modifying this component (costing $150-300) optimizes power delivery for specific conditions. A steeper angle provides quicker backshifting for technical terrain, while a shallower angle maintains higher gears longer for open trails and dunes.

Spring rate changes are among the most affordable upgrades at $50-150, altering engagement RPM and clutch pressure. Stiffer springs engage at higher RPMs for more aggressive starts, while softer springs provide smoother engagement for technical riding.

A performance drive belt might seem simple, but it's one of the most effective drivetrain upgrades. Stronger construction reduces slippage and power loss, effectively giving you more power without touching the engine. The $150-350 investment often pays for itself in reduced belt failures and consistent performance.

If you're riding in mud, you'll benefit from heavier weights and stiffer springs that maintain engine RPM when you hit resistance. Sand riding typically calls for lighter weights with specific helix angles to maximize top speed. For trail riding, aim for a balanced approach that gives you good low-end response while still allowing decent top speed.

As one customer told us after a clutch upgrade: "It's like I got a whole new machine. The power is actually getting to the ground now instead of cooking my belt."

Turbocharging 101

For those seeking dramatic power increases, nothing compares to adding forced induction. Turbocharging your UTV can provide eye-widening performance gains, but it requires careful planning and implementation.

At its core, a turbocharger compresses incoming air, allowing more oxygen into the combustion chamber. More oxygen plus more fuel equals more power—it's that simple. Most stock UTV engines can safely handle 5-8 PSI of boost, with each PSI adding roughly 3-5% more power.

A complete turbo system includes several key components working together. The turbocharger itself compresses the air, while an intercooler cools that compressed air for greater density. A blow-off valve releases pressure when you close the throttle, and a wastegate controls maximum boost pressure to protect your engine. Oil lines provide crucial lubrication to the turbo bearings, while charge tubes route the compressed air to your engine. Tying it all together, an ECU tuner adjusts fuel and timing to accommodate the forced induction.

Quality turbo kits typically cost $3,500-7,000, with professional installation adding another $1,000-2,000 if you're not comfortable doing it yourself. The installation process usually takes 8-20 hours depending on experience level and kit complexity.

For reliable operation, you'll want to consider supporting modifications. Lower compression pistons are recommended for high boost applications, while an upgraded fuel system ensures your engine gets the additional fuel it needs. Stronger connecting rods become important if you're pushing high boost levels, and an improved cooling system helps manage the additional heat generated by forced induction. And don't forget—you'll need to run premium fuel (91+ octane) in a turbocharged UTV.

The payoff? Expect 30-50% more horsepower at moderate boost levels (5-8 PSI) and potentially 50-100% more horsepower at high boost levels (10-15 PSI). You'll also enjoy significantly improved torque throughout the RPM range and better performance at altitude due to the forced air density.

A properly installed and tuned turbo system can be surprisingly reliable. Conservative boost levels (5-7 PSI) minimize stress on stock components, though regular maintenance becomes even more critical. Engine lifespan may be reduced at high boost levels, so consider your priorities and riding style when deciding how much boost to run.

As one of our turbocharging experts notes: "Running aggressive mud or paddle tires can significantly rob power from your motor, which turbocharging helps to offset." This makes turbocharging particularly valuable if you've upgraded to larger, more aggressive tires that demand more power to turn.

Common upgrade mistakes to avoid

Even the best UTV engine parts can't overcome poor installation or maintenance practices. Here are the pitfalls to avoid when upgrading your UTV:

Over-revving during break-in is perhaps the most common mistake new builders make. That freshly built engine needs time to properly seat rings and bearings. Revving too high too soon can cause permanent damage that no amount of quality parts can overcome. Follow a structured break-in procedure that gradually increases load and RPM over the first 100-200 miles.

Poor tuning after modifications is another performance killer. Adding parts without adjusting fuel and timing is like putting premium gas in a car with a dirty carburetor—you're not getting the benefits you paid for. Always ensure your ECU is properly tuned for your modifications, either through a programmer or professional tuning service.

Don't cut corners on filters and fluids. That $15 you saved on a cheap air filter might cost you $1,500 in engine damage down the road. Quality filters and manufacturer-recommended (or better) fluids are your engine's first line of defense against premature wear and failure.

Mismatched components create bottlenecks in your performance. Adding a big turbo without upgrading the fuel system, cooling, or clutching is like putting racing slicks on a car with worn brake pads—you're setting yourself up for problems. Plan your build as a complete system where each component complements the others.

Before making any modifications, document compression readings, temperatures, and performance metrics. Without these baseline measurements, you won't be able to accurately assess the impact of your modifications or diagnose future issues.

Ignoring torque specifications is a recipe for disaster. Engine components require precise tightening—too tight can stretch fasteners or distort components, while too loose can allow parts to move or fasteners to back out. Always use a torque wrench and follow manufacturer specifications.

When adding power, your drivetrain, cooling, and braking systems will face increased demands. Upgrade these supporting systems proportionally to maintain reliability and safety. Your UTV is only as strong as its weakest link.

Proper clutch tuning is essential when adding power. Without it, you'll likely experience belt failures, overheating, and poor performance. Match your clutch setup to your power level and riding style for optimal results.

More power generates more heat, so ensure your cooling system is up to the task. Larger radiators, high-flow water pumps, or oil coolers might be necessary depending on your power goals and riding conditions.

Finally, don't rush the process. Quality builds take time and attention to detail. Rushing through modifications often leads to overlooked details and future problems. Be methodical and thorough, even if it means your UTV is off the trail a bit longer.

The image above shows a melted piston—a costly reminder of what happens when proper tuning is neglected after adding performance modifications. This particular owner added a turbocharger but failed to adjust the fuel mapping, resulting in a lean condition and catastrophic engine failure. This single mistake cost thousands in repairs and significant downtime—all avoidable with proper planning and execution.

With the right approach and quality UTV engine parts, your performance upgrades can provide years of improved riding enjoyment without sacrificing reliability. At Rad UTV Parts, we're always happy to help you plan a balanced upgrade path that matches your riding style, budget, and performance goals.

Frequently Asked Questions about UTV engine parts

What's the biggest sign my drive belt is shot?

That telltale moment when your UTV suddenly feels like it's not quite connecting to the ground properly? That's your drive belt slipping – and it's the number one sign that replacement time has arrived.

When I'm inspecting belts for customers at Rad UTV Parts, I always look for visible cracks on both the inner and outer surfaces first. Even tiny cracks are early warning signals that your belt is starting to deteriorate. Another dead giveaway is when the sides of the belt develop a glossy, shiny appearance – that glazing indicates heat damage that's already compromised the belt's integrity.

Fraying edges where you can see exposed cord material means you're living on borrowed time, and if you spot actual chunks missing from the belt, you should park your UTV immediately until you can replace it. Many riders also report a distinctive burning smell when a belt is on its last legs – that's the rubber overheating as it slips against the clutch faces.

Most manufacturers (and we at Rad UTV Parts) recommend checking your UTV engine parts like drive belts every 500 miles and replacing them preventatively around the 1,500-2,000 mile mark. That this interval shrinks dramatically if you're splashing through mud holes, crossing water, or driving aggressively.

Here's a tip from someone who's been stranded more than once: always carry a spare belt and the basic tools needed for trailside replacement. Nothing ends a great day of riding faster than a belt failure 20 miles from the nearest road!

Do aftermarket pistons shorten engine life?

This is one of those myths that just won't die in the UTV community. The truth? Quality aftermarket pistons from reputable manufacturers absolutely do not shorten engine life – and in many cases, they can actually extend it.

The key word here is "quality." Premium aftermarket pistons often use superior materials compared to OEM options, including forged aluminum alloys that offer significantly better strength than the cast pistons that come stock in many UTVs. Many aftermarket options also incorporate smart design improvements that address known weaknesses in factory pistons, like thicker crown areas or improved ring lands that better handle the stresses of high-performance riding.

That said, the installation process matters enormously. I've seen perfectly good UTV engine parts fail prematurely because someone rushed the installation or didn't properly hone the cylinders. Proper clearances and meticulous assembly are just as important as the pistons themselves.

Engine tuning is another critical factor. If you upgrade to higher compression pistons but don't adjust your ECU accordingly, you're asking for trouble. The pistons themselves aren't the problem – it's the mismatch between components that causes issues.

For weekend warriors who just want reliability, high-quality OEM-replacement pistons are usually perfect. But if you're running higher boost levels, tackling extreme terrain, or just want that extra insurance against failure, premium aftermarket pistons from brands like JE, Wiseco, or CP-Carrillo can be well worth the investment.

Will a turbo kit void my warranty?

This question comes up in our shop almost daily, and the answer isn't as straightforward as most riders hope. Let me break it down in plain English.

Thanks to the Magnuson-Moss Warranty Act (a federal consumer protection law), manufacturers can't automatically void your entire warranty just because you've added aftermarket UTV engine parts. However – and this is a big however – they can deny coverage for specific problems that your modifications caused or contributed to.

Think of it this way: If you install a turbo kit and later have a transmission issue that's completely unrelated, the manufacturer should still honor the warranty for that transmission repair. But if your engine internals fail because they couldn't handle the extra heat and pressure from forced induction? That's likely coming out of your pocket.

Different UTV manufacturers have very different attitudes about modifications. Some brands are relatively mod-friendly as long as the work is done properly. Others take a much harder line, especially with engine modifications that fundamentally change how the powertrain operates. A few manufacturers explicitly state in their warranty documentation that turbochargers and similar power-adders will void powertrain coverage, period.

If warranty coverage matters to you, I recommend a few precautions: - Read your warranty documentation thoroughly before modifying anything - Consider waiting until your factory warranty expires before adding major power mods - Choose quality components installed by shops with proven track records - Keep detailed records of all modifications and maintenance - Look into aftermarket extended warranties designed specifically for modified vehicles

The team at Rad UTV Parts is always happy to discuss your specific situation and help you weigh the tradeoffs between performance upgrades and warranty considerations. We've helped thousands of riders find the right balance for their needs and riding style.

Conclusion

When you think about it, your UTV's engine is truly the beating heart of your off-road trips. Throughout this guide, we've explored the essential UTV engine parts that keep your machine running strong, from basic maintenance to exciting performance upgrades. The knowledge you've gained here will help you make smarter decisions about your UTV's engine components, whether you're fixing what's broken or dreaming about what could be.

Taking good care of your UTV's engine delivers benefits you'll feel with every ride. Proper maintenance restores your machine to its original capabilities, while thoughtful upgrades can transform an ordinary ride into something extraordinary. There's nothing quite like the confidence that comes from knowing your UTV won't leave you stranded in the middle of nowhere because you've invested in quality UTV engine parts and proper installation.

Your UTV represents a significant investment, and proper engine care helps protect that investment in multiple ways. Regular maintenance dramatically extends your machine's useful life, while documented service history significantly boosts resale value when it's time to upgrade. Perhaps most importantly, customizing your UTV's performance characteristics to match your specific riding style and terrain creates a personalized experience that makes every trip more enjoyable.

As you plan your next maintenance routine or dream up your ultimate performance build, remember these simple principles that will save you time, money, and frustration:

First, budget wisely by putting your money where it matters most for your riding style. Not every shiny upgrade makes sense for every rider – focus on the UTV engine parts that will deliver the most meaningful improvements for how you actually use your machine.

Second, approach upgrades systematically to ensure balanced performance. Adding massive horsepower without upgrading supporting systems is a recipe for expensive failures. Think of your UTV as an ecosystem where every component needs to work in harmony.

Third, even the best components need regular care. The most expensive performance parts in the world won't save you from the consequences of neglected maintenance. Develop and stick to a maintenance schedule that keeps everything running smoothly.

Finally, keep detailed records of everything you do to your UTV. This documentation becomes invaluable for troubleshooting issues and significantly increases resale value by giving the next owner confidence in your machine's history.

At Rad UTV Parts, we're genuine off-road enthusiasts who understand the thrill of a perfectly running machine. Our extensive selection of quality UTV engine parts and accessories is backed by our Price Match Guarantee and supported by people who actually ride what they sell. Whether you're changing your oil or building a turbo monster, we have the parts and knowledge to support your vision.

Thanks for spending time with our comprehensive guide to UTV engine parts and performance upgrades. Your next trip is waiting—and with the right parts and preparation, it's going to be amazing. Ready to hit the trail? We'll see you out there!

Ready to transform your UTV's performance? Explore our complete lineup of engine components, performance upgrades, and accessories at Rad UTV Parts. From basic maintenance items to advanced performance modifications, we have everything you need to power up your ride.